Technologies

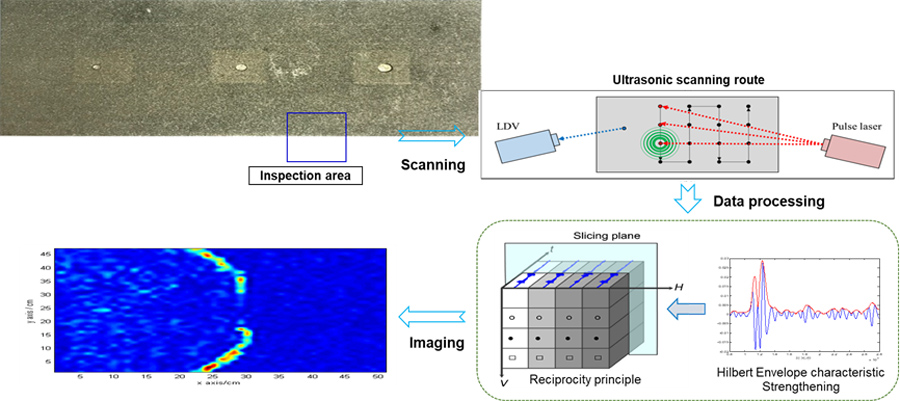

Metal additive manufacturing has been widely applied in aerospace/defense /automobile industries etc., while as defects like multi-metal composite material manufacturing and sensor embedment etc. cannot be eliminate effectively by the current process and technology. The testing equipments for metal parts at present are usually off-line, for the inner defects already formed, reprocessing is impossible. Reproduction is only choice left which causes great waste.

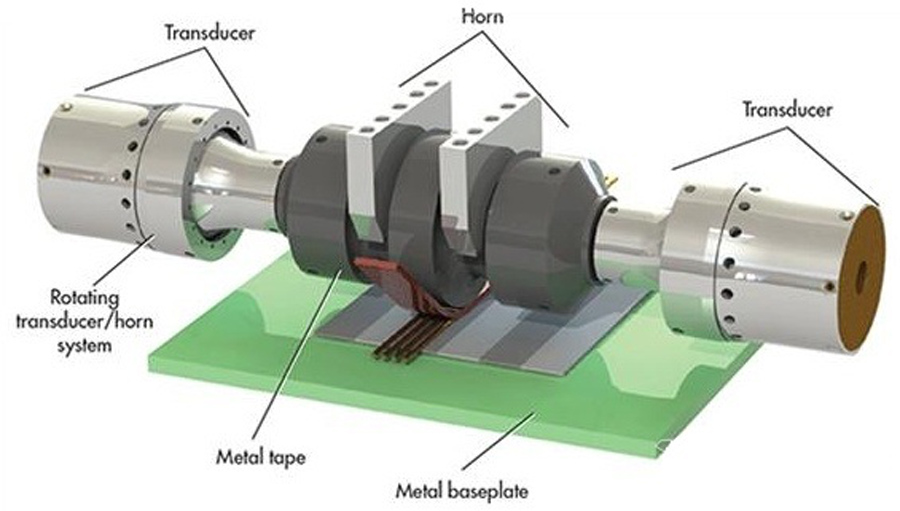

In contrast, on-line detection has a higher real-time performance and higher efficiency. It provides timely defects feedback on the new layer forming, forms a manufacturing-detection closed loop which improves the yield at the end. Integrated ultrasonic additive –subtractive manufacturing and detection equipment combines all advantages of additive, subtractive manufacturing and on-line detection together, it provides a solution decrease the defects and increase production.

If you want to learn more about or involve in this project, please contact Ms. Ying HOU at houying@niiam.cn.

Wechat

Wechat Facebook

Facebook Linkedln

Linkedln Twitter

Twitter