Technologies

With the advent of industrial technology, the requirements of structure optimization and precision parameters for parts in aviation and aerospace are getting higher and tougher. The manufacturing demand of high precision parts with complex geometry such as inner cavity and inner port, is increasing. While as with machining accuracy and surface quality guaranteed, the cutting tools of traditional machining method restricts the efficiency and precision consistency. Additive manufacturing is most ideal solution for complex parts forming, but still it is hard to meet the requirements of high precision and high surface quality.

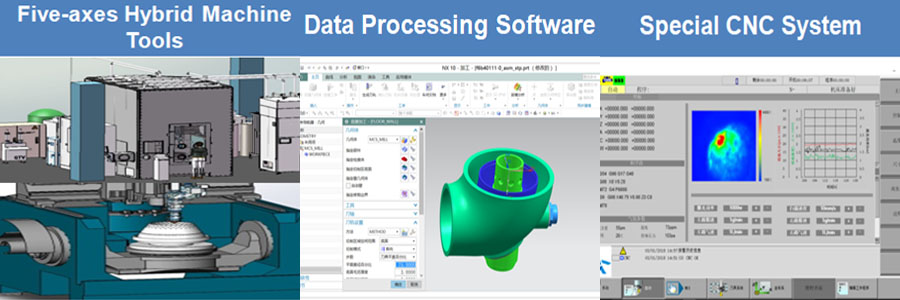

This project aims for manufacturing of small and medium-sized complex precision structural parts to develop additive-subtractive integrated manufacturing technology. The team currently chose manufacturing and repairing of aerospace engine structure, molds with inner manifold etc. complex components as application targets, focusing on the researching of five-axial LMD additive and subtractive manufacturing technology of metal materials such as stainless steel, high temperature alloy, titanium alloy.

Functions

Inert gas enclosure

Touch probe for form accuracy

In-situ inspection on melten pool

Closed-loop control

If you want to learn more about or involve in this project, please contact Dr. Fei XUE at xuefei@niiam.cn.

Wechat

Wechat Facebook

Facebook Linkedln

Linkedln Twitter

Twitter